Features:

- Capacity range: 10TR to 300TR

- Temperature range: (+) 17°C to (-) 40°C

- Suitable for various refrigerants: -R 717 (Ammonia) , R 404a, R 134a, R 22, R 23

- Energy efficient

- Reputed reliable compressors

- Water cooled condenser shell & tube type with Seamless tubes

- With High efficiency, high heat flux tubes of WIELAND, Germany make in Copper (For non Ammonia)

- With SS 304 (optional on request)

- Evaporator (Chiller) shell & tube with seamless tubes

- With High efficiency, high heat flux tubes of WIELAND, Germany make in Copper ( for non Ammonia)

- With SS 304 (optional on request)

- Skid and equipments duly sandblasted and painted.

- Factory built self contained ready to commission

- Customized design and development e.g. Dual temperature operation, Hazardous area classification

- PLC based control panel user friendly, necessary safety interlocks and auto manual operation of the chiller. Provision for communication with DCS/SCADA, Data logger

- Compressor drive motor starter panels - Star-Delta, Soft starter, VFD with reputed switch-gears makes

- Instruments & controls of reputed makes as per Industry standards

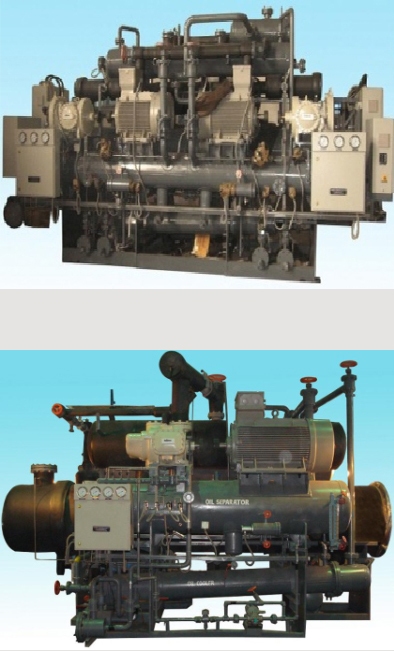

These packages with reciprocating compressors have been slowly phased out due to high preference for screw chillers due to drawbacks of reciprocating compressors such as large number of moving parts , early wear n tear of these parts, high operational cost, falling volumetric efficiency (hence continuously increasing specific power consumption) over a period of time,etc. Besides, price of screw compressors are getting reduced as the volume production increases and hence no price advantage for reciprocating compressor based chillers and systems.

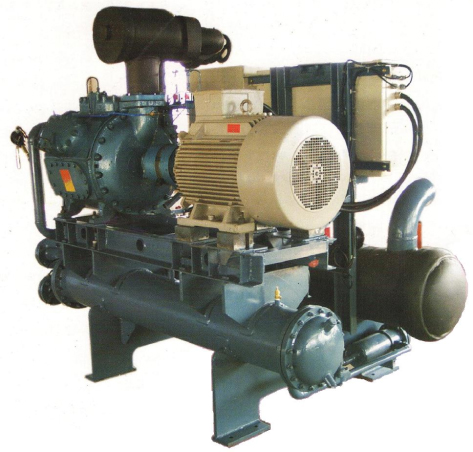

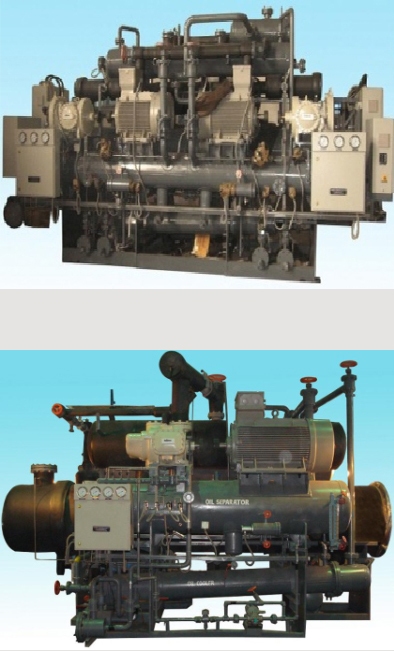

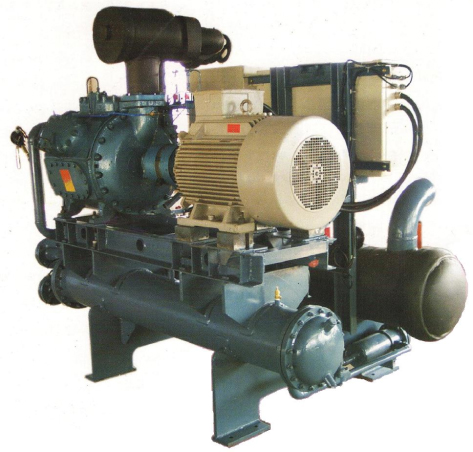

Screw chillers with Open type compressors

Features:

- Capacity range: 30TR to 750TR

- Temperature range: (+) 17°C to (-) 75°C

- Suitable for various refrigerants: - R 717 (Ammonia), R 404a, R 134a, R 22, R 23

- Reliable, Energy efficient

- Reputed internationally known single and twin screw compressors

- Water cooled condenser shell & tube type with Seamless tubes

- With Finned Carbon steel, SS 304 (Optional on request)

- With High efficiency, high heat flux tubes of WIELAND, Germany make in Copper (for refrigerant other than Ammonia),

- With SS 304 (Optional on request)

- Evaporative condenser having coil bundle in SS 304 tubes (mainly for Ammonia refrigerant)

- Evaporator (Chiller) shell & tube - Flooded, DX type with seamless tubes

- With Carbon steel, SS 304 (Optional on request)

- Plate type heat exchangers (PHE) with SS 316 plates of reputed internationally known makes

- Skid and equipments duly sandblasted and painted.

- Factory built self contained ready to commission

- Customized design and development e.g. Two stage, Dual temperature operation, Hazardous area classification

- PLC based user friendly control panel, necessary safety interlocks and auto manual operation of the chiller. Provision for communication with DCS/SCADA, Data logger

- Compressor drive motor starter panels - Star-Delta, Soft starter, VFD with reputed switch-gears makes

- Instruments & controls of reputed makes as per Industry standards

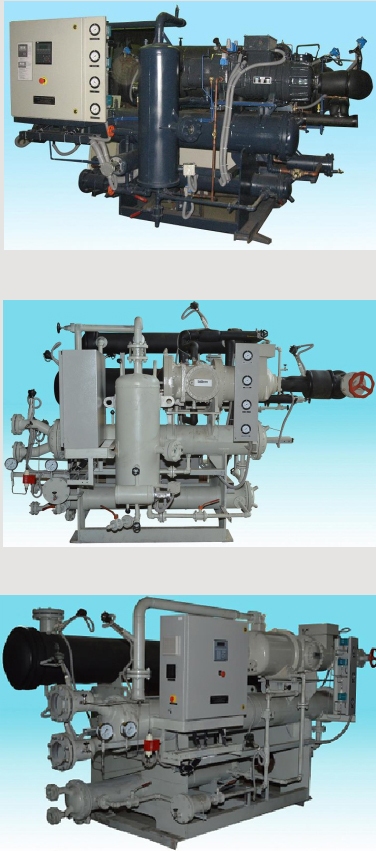

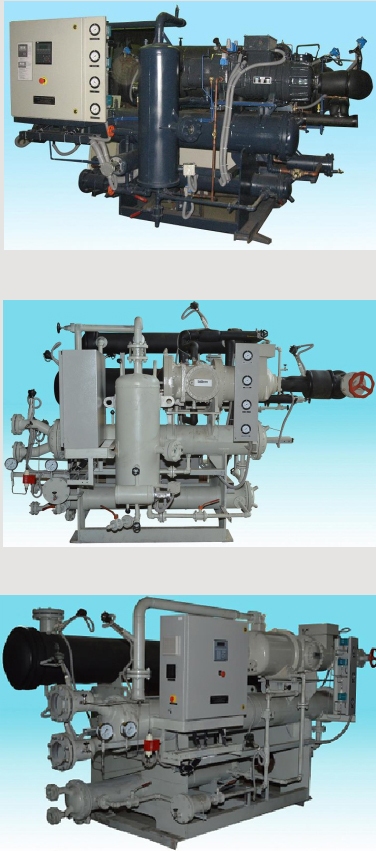

Screw chillers with Semi-hermetic type screw compressors

Features:

- Capacity range: 30TR to 500TR

- Temperature range: (+) 17°C to (-) 40°C

- Suitable for various refrigerants: -R 404a, R 134a, R 407C, R 22, R 23

- Reliable , Energy efficient

- Reputed internationally known single and twin screw compressors

- Water cooled condenser shell & tube type with Seamless tubes

- With High efficiency, high heat flux tubes of WIELAND, Germany make inCopper

- With SS 304 (optional on request)

- Evaporator (Chiller) shell & tube with seamless tubes

- With High efficiency, high heat flux tubes of WIELAND, Germany make inCopper

- With SS 304 (optional on request)

- Skid and equipments duly sandblasted and painted.

- Factory built self contained ready to commission

- Customized design and development e.g. Dual temperature operation, Hazardous area classification

- PLC based control panel user friendly, necessary safety interlocks and auto manual operation of the chiller. Provision for communication with DCS/SCADA, Data logger

- Compressor drive motor starter panels - Star-Delta, Soft starter, VFD with reputed switch-gears makes

- Instruments & controls of reputed makes as per Industry standards

With more than three decades of experience in industrial refrigeration with screw and recip chillers, to cater to smaller capacity range, we are developing the scroll chillers. These will be very compact complete with brine tank with circulating pumps and hence will be self sufficient systems. These will be developed both in air cooled and water cooled versions.

Features:

Features: Features:

Features: Features:

Features:

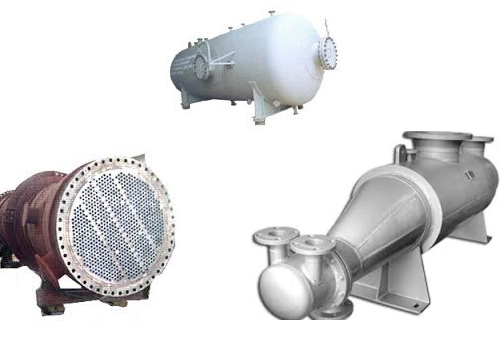

We have a special project and engineering section that is exclusively for projects requiring detailed engineering and special execution. We design, engineer and manufacture the packages to comply with requirements of various Codes and standards like API, CE, ASME, TEMA, PED Etc. This division also carries out engineered projects for Poultry, Dairy, Brewery, Textile and allied industries requiring special application of refrigeration.

We have a special project and engineering section that is exclusively for projects requiring detailed engineering and special execution. We design, engineer and manufacture the packages to comply with requirements of various Codes and standards like API, CE, ASME, TEMA, PED Etc. This division also carries out engineered projects for Poultry, Dairy, Brewery, Textile and allied industries requiring special application of refrigeration.